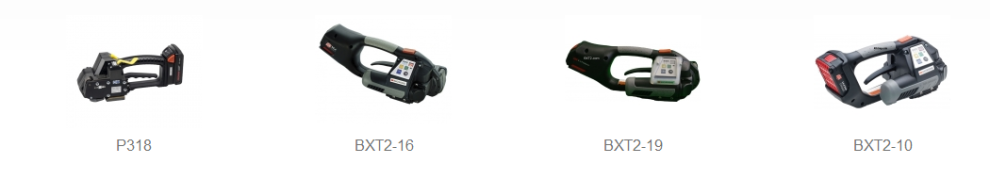

Old-fashioned manual strapping tools have taken a backseat these days, making way for battery powered strapping devices. Different companies have come forward with their bouquet of manual or automatic products, aiming to make the strapping task easier and cost-effective. Signode tools deserve special mention in this regard because of their innovative technologies. The fact that entire tensioning, friction weld sealing and cutting can be completed with press of a single button, adds greater charm to battery powered strapping devices.

The Signode BXT2-19 is one such tool which has gained vast recognition because of its superb speed and accuracy. While it basically supports 5/8″ or 3/4″ polyester strapping, flexibility is there for different width strapping too. Very smooth and efficient operation makes this tool a favored option among buyers from varied industrial sectors.

Key features and specifications of BXT2-19

- It supports polyester and polypropylene strapping of strap dimension 5/8”-3/4″ x .016 – .041”

- Strap tension ranges between 1200 to 4000N in standard mode and 400 to 1600N in light tension mode

- The machine weighs around 4 kg

- Friction weld sealing technology is provided

- The tool is equipped with lithium ion and brushless motor techniques

BXT2-19: The right choice for your applications

If your requirement includes strapping in difficult and different positions, then this lightweight and ergonomically comfortable strapping device will surely fulfill your purpose. The tool comes with a tight grip on the handle and can be easily operated horizontally, vertically and upside down, as per the sealing requirement. What is further appealing about this strapping tool is that it accommodates varied load types. So it doesn’t matter if you have light or heavy duty banding need, the tensioning force can be adjusted from a wide range of 88 to 880 pounds. Then you can’t overlook benefits offered by the brushless motor technology and innovative battery design. With these techniques, you not only remain sure about the tool’s consistent performance but need not worry about its sudden breakdown too. Wear parts being available easily make maintenance or repair of the tool simple and less time-consuming.